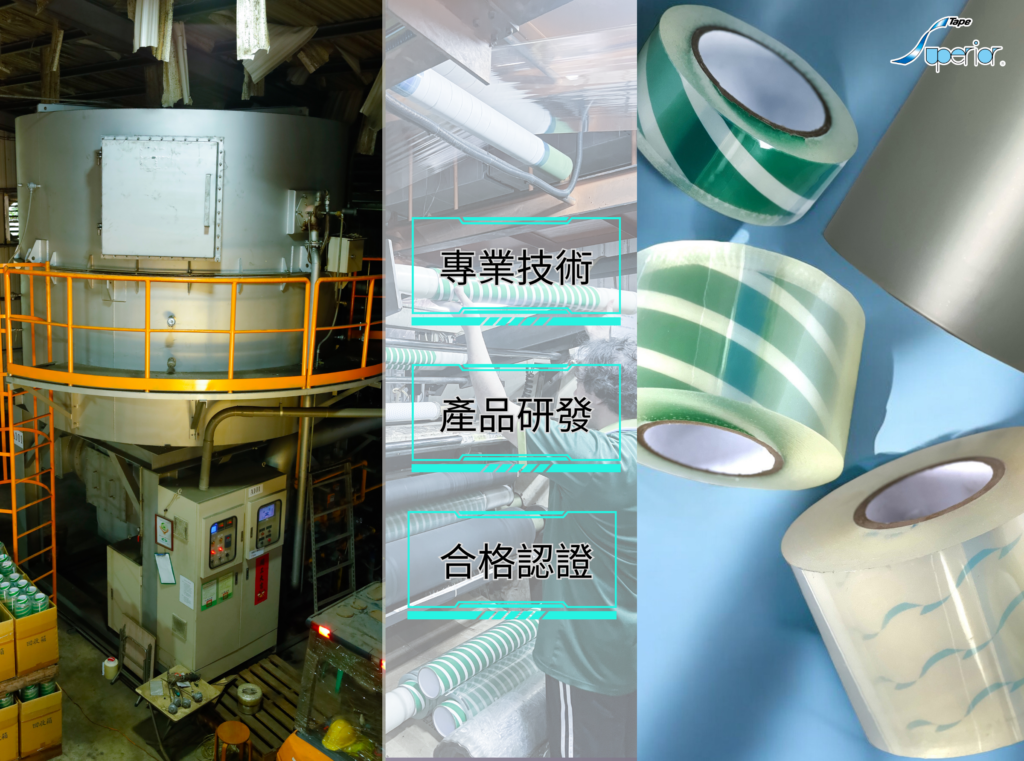

Superior Tape® is a Taiwanese company that sells BOPP lamination tape. The process of research&development and manufacture are all completed in Taiwan. All materials are meticulously chosen from Taiwan as well.

0

+

38 Years Of Experiences

0

+

Products

0

+

Clients

0

+

Like